HVAC Solution System

HVAC Solution System

HVAC usually refers to the mechanical system of the building that provides heating, ventiltion and cooling within a building or a premise. This includes air conditioners, blower assembly, an evaporative coil, a compressor and compressor coil, thermostats, duct work and filters which helps to distribute the conditioned air within a building.

Our expertise includes seamless integration of Turnkey Projects which includes:

Air Handling Unit

Available with us, is quality proven range of air circulation systems that is used for rapidly ventilating an enclosed area with fresh external air. Offered in standard and dual mode operations, these air circulation systems are offered to our clients in standard and customized specifications.

The Mode of operation of the dual circulation systems in mentioned blow:

Filters

High efficiency particulate Air (HEPA)

Ultra low penetration air (ULPA)

Most UPLA filters are replaceable extended media dry filters that have a minimum particle collection efficiency of 99.9997% efficient for particles greater than or equal ot 0.12-micron in size.

Filter » TypeEfficiency R (%)

Ducting

The most common type of duct construction are:

Sheet Metal Type - It is the most common type of ridged air duct fabricated out of galvanized steel or aluminium. The Construction may be round, rectangular, or in the form of a spiral oval.

Fibreboard -Fibreboard air ducts are fabricated with boards of compressed resin bonded inorganic glass fibres. They have a foil face on the outside the serves as the air barrier and water vapour retarder. The interior of fibreboard air duct is sealed to prevent fibreglass fibers from entering the air stream.

Flex-line air ducts -flexible air ducts are fabricated with a spring steel wire helix encapsulated in a 2-ply, polymer plastic.

Flexible air ducts.

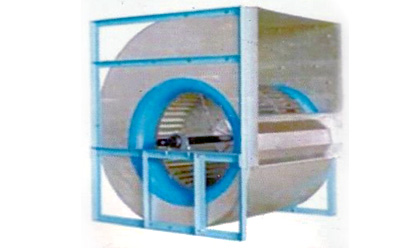

Blowers: Air Handling Blowers

Available with us, is a quality proven range of Air Handling Blower that is used for rapidly ventilation an enclosed area with fresh external air. Offered in standard and dual mode operations, these air circulation systems are offered to our clients in standard and customized specifications. This Blower is mainly use in AHU Section & Air conditioning system.

Exhaust Blowers

We hold expertise in designing and manufacturing a heavy duty range of exhaust fans that find extensive application in foundries, mills and chemical plants for material handling purposes. These highly efficient exhaust fans are suitable for transferring material such as paper, sawdust sand, shavings and many other products. Available in the size range of 12' diameter to 84' diameter, and capacities up to 1,75,000 MCH at 150mm SWG, these exhaust fans are offered to your clients at most competitive prices.

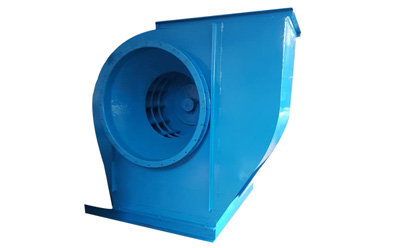

Centrifugal Blower

To avoid unnecessary delay in correspondence and to enable us to suggest a suitable type of equipment. We request that the following date should necessarily be furnished while. Forwarding your enquiries to us:

Note: Unless otherwise specified. The units are supplied with clockwise direction of rotation and discharge at horizontal bottom right (as viewed from suction end) corresponding to R-1.