Spray Dryer

Spray Dryer

Spray drying is a method of producing a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods & pharmaceuticals. A consistent particle size distribution is a reason for spray drying some industrial products such as catalysts. Air is the heated drying medium; however, if the liquid is a flammable solvent such as ethanol or the product is oxygen sensitive then nitrogen is used.

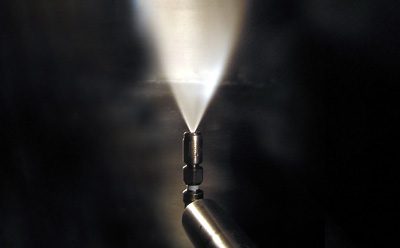

A spray dryer takes a liquid stream & separates the solute or suspension as a solid & the solvent into a vapour. The solid is usually collected in a drum or cyclone. The liquid input stream is sprayed through a nozzle into a hot vapour stream & vaporised. Solids form as moisture quickly leaves the droplets. A nozzle is usually used to make the droplets as small as possible, maximising heat transfer & the rate of water vaporisation.

Application of Spray Dryer

Spray Dryer LAB SCALE

Variants: 0.5 ltr to 1.5 ltrs/hr water evaporation rate.

Spray Dryer PILOT SCALE

Variants: 5 ltrs to 25 ltrs/hr water evaporation rate.

Spray Dryer PRODUCTION SCALE

Variants: 50 Itrs to 100 Itrs/hr water evaporation rate.

There Are 4 Types Of Atomization Techniques

Pressure Nozzle

Two-Fluid Nozzle Atomization

Ultrasonic Nozzle

Rotary Atomizer